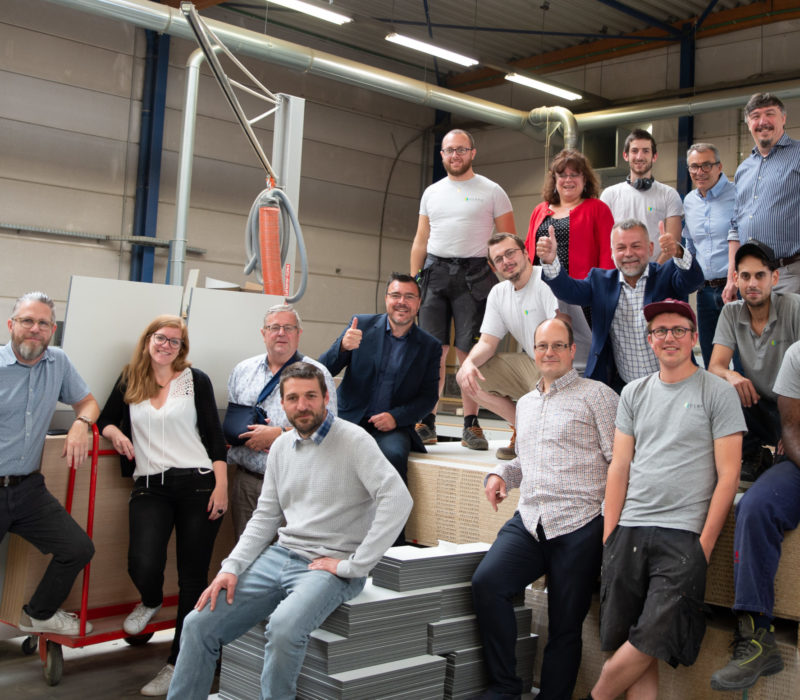

A nearby and family company

We put our skills at the service of your specific requirements related to laboratory furniture

- Our practical and flexible approach takes your realities into account

- A personalized support to the project is provided by a commercial supervisor and a project manager. All commitments are strictly respected.

- Our company has its own design department, which makes it possible to be technically creative and imagine customized furniture

- In our working places our staff can manufacture very high-quality furniture thanks to years of experience

- Our dedicated teams supply and install your order.

Quality and sustainability

Since 1956 Derpa is specialized in laboratory furniture. We supply medical, pharmaceutical, chemical and nuclear laboratories as well as university research centers and the industry. We produce made-to-measure furniture and use high quality materials. Today Derpa employs a dozen people. The yearly turnover amounts a few million euros. Every year a few thousand products quit our working places to be perfectly integrated into laboratories and research centers. Both In Belgium and abroad Derpa plays a major role in laboratory furniture. We are the Belgian market leader for massive laminate furniture. That type of material is particularly well-suited for laboratory work, with essential properties for environments for which hygiene and cleanliness are an absolute necessity.

Our furniture is designed to be durable and robust. We consider the specific stresses to which the equipment will be subjected. Also ergonomics, security for people and ease of use are essential. In addition aesthetics became also very important over the years.

Custom-made service

Because every laboratory staff member has its own needs, we can adjust design and manufacturing process to every single situation. Our approach is clear : looking together for the most appropriate solution matching your particular case. With Derpa you have services and solutions that can meet the very specific requirements for your laboratory development, regardless of its size. You need simple storage cabinets or a very advanced lab design? We have a solution. All our products can be customized according to your specific needs.

Designed from A to Z

As we manage the whole production process by ourselves, from design to installation on-site, we are able to strictly control the manufacturing and offer an absolute quality guarantee. Added to efficient stock management, this allows us to offer highly competitive product prices.

Our design department

Assignment: conceiving laboratory solutions and drawing up of 2D and 3D plans for your project

- Discussion with our client

- Feasibility study

- Drawing plans

Production unit

Skilled personnel for professional service and quality products

- Woodworking : cutting, working, assembling, pre-installation

- Metal working: cutting, folding, certified welding, finishing / polishing

- Fluid management and special techniques: electricity, water, gas, HVAC services

Project management

A team of experts listens to you. Their task: to guide you in equipment and design projects

- Price offer

- Planning

- Follow-up

- Acceptance

Mounting and installation

From supply to complete installation, our skilled installing teams cover all the steps to supply really made-to-measure furniture: specific mountings, fluid and gas connections, suction systems and commissioning.

A state-of-the-art production tool

In our working places all steps of furniture production are covered: from design to installation, from manufacturing to packaging. Programming and metallic laser cutting, assembling, semi-automatic or TIG-welding, digital edgebanding based on optimization software, reducing of wastewood and cutouts per lot or quantity, gluing edges on automated production lines and conveyor belts. We own a large self-adjusting electromechanical clamp that enables us to rapidly assemble and glue a whole party. All specific drilling and cutting operations are managed thanks to a four-axle central machine with several distinct working tools hosted in a double automated store. Thanks to design and development software we can manage the evolution of the range and produce